What Hydraulic Fluid to Use

There are many different fields in which hydraulic systems provide essential functions!

Mechanic shops rely on them to power car lifts. They can be located in the booms of various construction machinery.

Hydraulic systems are surprisingly common and necessitate specific hydraulic fluid. But how do you know what hydraulic fluid to use?

Types of Hydraulic fluid

1. Synthetic Ester-Based Hydraulic Fluids

Using alcohol and fatty acid, one can create a synthetic ester. Using different alcohols and fatty acids results in vastly different environmental qualities.

In addition to lowering energy consumption and carbon dioxide emissions, modern hydraulic fluids that are biodegradable and have an ecological classification often have superior technical properties to conventional mineral oils. Because of this, many hydraulic systems use them.

2. Mineral Oil-Based Hydraulic Fluids

Mineral oil, the most common base oil, is typically categorized into three subsets: I, II, and III.

Mineral oils traditionally processed using a solvent are classified under Group I. Hydrocracked mineral oils from Groups II, and III are more refined than Group I oils regarding sulfur impurities and have a thicker consistency. The number of refineries producing Group I oils will decline or switch to making Group II oils, hastening the shift from Group I to Group II during the next few years.

3. Vegan Hydraulic Fluids

Oil extracted from plants is the foundation of vegetable hydraulic oil. These oils are usually natural and have excellent environmental features, and their restricted technical properties mean that they are not now commonly employed.

Special Hydraulic Fluid Needs

In addition, there is a specialized variety of hydraulic fluids for use in high-stress applications. In the food business, for instance, fluids must be highly pure (certified for accidental contact with food), safe, and technically effective for obvious reasons. Other industries that place stringent requirements on fire safety include mining, steel, and aviation.

The Environment and Hydraulic Fluids

Misconceptions about rapeseed-based environmental oils, the first generation of its kind, persist even now. Leave them in the past! These days are not the same. Biodegradable, environmentally classed hydraulic oils, often based on synthetic esters, are presently the most effective option for most hydraulic systems due to their superior technical performance compared to conventional mineral oils (which are not environmentally classified).

Factors in Choosing the Right Hydraulic Fluid

Hydraulic fluid’s primary function is to prevent corrosion, wear, and oxidation in hydraulic systems. The characteristics of fluids range widely from one type to the next. Due to these distinctions, every kind of hydraulic oil serves a unique function.

Hydraulic fluid performance is determined by water resistance, viscosity, and heat dissipation. To that end, you should select a fluid to deliver the desired results for the intended use. When choosing, it’s also essential to consider the operational conditions.

But what are the most important considerations for selecting the hydraulic fluid?

1. Design of a Hydraulic Pump

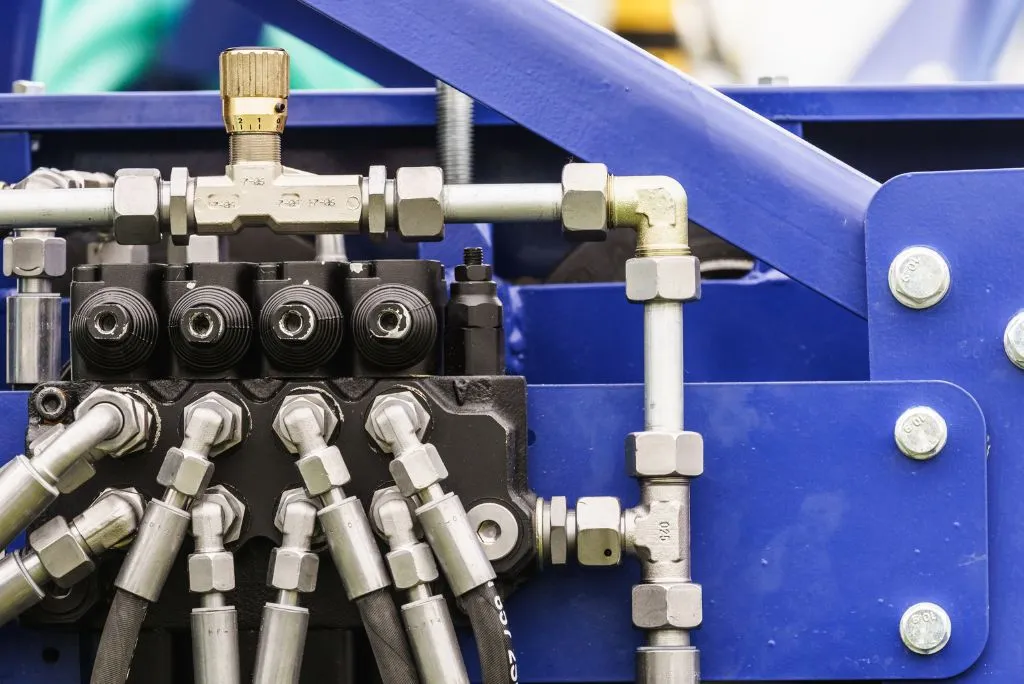

Choosing the correct hydraulic fluid may affect the hydraulic system’s architecture. Standard hydraulic pump designs include:

- Injectors with a vane.

Fluid flow is maintained at a constant rate by these pumps with the help of rotating motion, which is not affected by changes in pressure. Additionally, they are capable of functioning with minimal noise.

- A gear pump.

For pumping hydraulic fluid, they employ a network of gears. For high-pressure applications, gear pumps excel.

- Pumps with pistons

They generate substantial pressure in the hydraulic fluid via mechanical distribution with little effort. When volumetric efficiency is critical, piston pumps excel.

2. Classification of Request

You must consider the system’s function while selecting a hydraulic fluid. Using the proper fluid in your system improves performance and helps your machinery last longer.

Before deciding on a fluid type, it may be helpful to determine what makes a given application unique. A garbage truck, for instance, spends a lot of time in the open. The hydraulic fluid’s dependability will likely decrease if it gets wet or covered with debris or other pollutants. Also, the truck’s hydraulic system has a history of potential leaks.

3. OEM Suggestions

Your hydraulic equipment’s OEM may recommend a particular type of hydraulic fluid for its operation. The suggested fluid is often the tried-and-true option that has been shown to deliver optimal results.

The Original Equipment Manufacturer’s recommended fluid may be the only one covered under warranty. In that case, following the guidelines will help prevent losses in the future.