Marine Lubrication: Everything You Need to Know

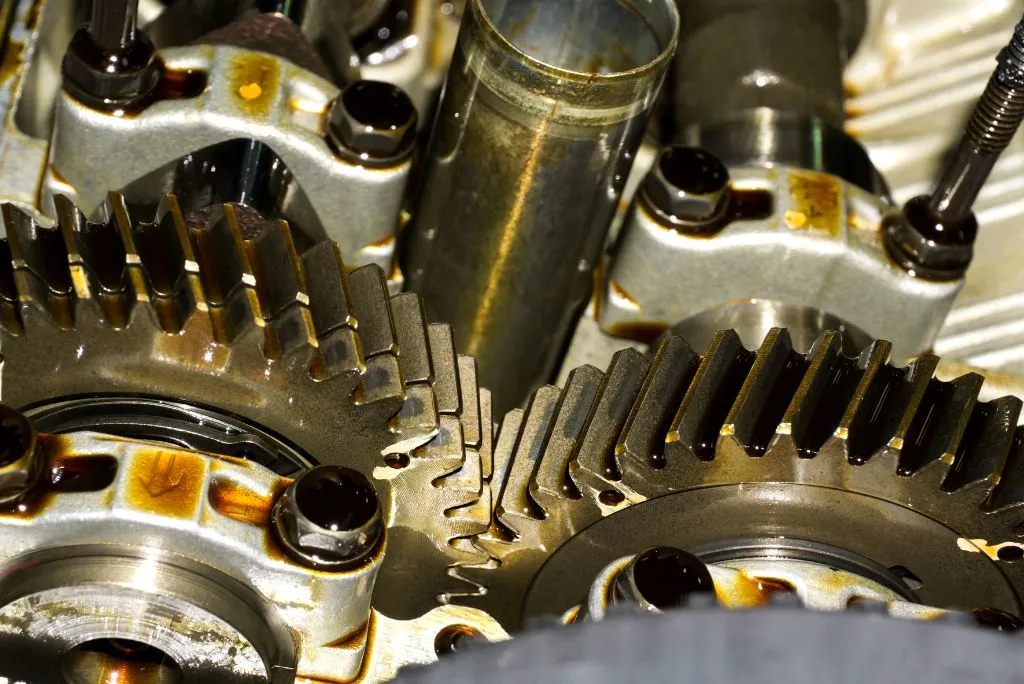

The engine’s lubrication system distributes oil to reduce friction between the machine’s many moving elements. Mainly, it facilitates the creation of an oil layer between the moving parts, which lessens the amount of friction and wear. In some engines, lubricating oil also serves as a coolant and is used as a cleaning.

Knowing the different marine lubricating systems can help you pick the best one for your marine vehicle!

How Do You Lubricate A Ship’s Engine?

Lubrication for marine engines typically falls into four categories:

- Hydrodynamic Lubrication

The engine oil forms a thick layer that separates the moving components. The film is produced by relative motion. It means that the system itself puts pressure on this sort of lubrication. - Hydrostatic Lubrication

Hydrostatic lubrication is so named because the moving parts’ motion precludes the oil film’s formation, as suggested by the term. As a result, a separate oil pump is required to supply the necessary oil pressure. The effectiveness of marine lubrication is determined by the clearance located on metal surfaces and the oil pressure at the entrance.

A crosshead lubrication pump raises the pressure of the hydrostatic lubricant used in crosshead bearings. - Lubrication Of The Boundaries

It happens whenever it’s impossible to make a film entirely made of fluid. To create the thin film, two moving surfaces must be brought into proximity to one another. High friction between these surfaces indicates some degree of metal-on-metal contact.

An off-center shaft, a slow speed, or a heavy load can all cause this phenomenon. Additionally, the low oil viscosity could be to blame. - To Lubricate Elastically and Dynamically

When significant elastic deformation of the surfaces occurs, the contact area’s lubricant film shifts in shape and thickness, a phenomenon known as elastohydrodynamic lubrication (EHD). It usually occurs when two moving surfaces touch one another, either by rolling or sliding.

Marine Engine Lubrication Systems

- Main Oiling System

Two pumps are used in the crankcase lubrication system. One pump will operate continuously, while the other will be in reserve. If the oil pressure drops or the primary pump breaks down, it kicks in.

A telescoping tube transports the oil to the crosshead. At that point, it travels to the main engine and lubricates various moving parts. The piston is cooled and lubricated in the first place. The crosshead bearing is the next stop. - Systems For Lubricating The Turbocharger With Oil

A turbocharger is an example of a component that spins very quickly in an engine. Use the exhaust from your boat’s engine to power the turbine. The primary function of the marine engine air intake is to supply combustion with oxygenated air.

Bearings in a turbocharger are mounted on the shaft, which rotates at high speeds and relatively easily carries hefty loads. - Cylinder Lubrication System

Cylinder lubrication is handled by its dedicated system. Piston ring lubrication is made possible by it. Multifaceted are the functions of the cylinder lubrication system, which include:- Decreased resistance between the rings and the liner.

- Sealing these parts together to prevent damage

- Protecting against rusting, for one.

- It also cleans out impurities in oils and gas.

Choosing the Best Marine Lubricant

Parts of marine engines are vulnerable to the effects of friction, corrosion, and wear and tear, no matter how intense the engine is. Their increased susceptibility to wear and tear is due to increased friction, corrosion, and general use.

Make sure the engine stays well-oiled so that it can perform reliably.

Its lubrication setup can either be integrated into the engine’s primary or operated separately.

Here are some qualities of an efficient marine engine lubrication oil that will ensure the turbocharger bearing lubrication system is adequately protected:

- Viscosity Of Oil

The viscosity of oil indicates its thickness and its fluidity at different temperatures. Oil with a high viscosity is very thick. At high temperatures, the thick coating formed by such lubes around the engine’s components is more effective at protecting it from damage. Conversely, low-viscosity oils are more fluid because they have a lower solids content. - Alkalinity

Sulfuric acid, released during fuel burning, can lead to acidic corrosion. High alkalinity in the oil is crucial for marine engines because it prevents acidic corrosion. - Resisting Oxidation

Lubricants in marine engines have air contact. For this reason, oxygen must always be present. Oxidation rates increase at high temperatures, leading to sludge development, bearing corrosion, and acid production. For this reason, lubricating oils typically contain anti-oxidation and anti-corrosion compounds. - Capacity To Carry Weight

This is because the oil’s viscosity affects how much weight it can transport. The marine engine’s internal components are relatively heavy. Therefore, the lube’s load-carrying ability must be sufficient to sustain the engine’s pressure. Avoid doing this, as it could speed up the wear and tear on the engine due to the increased friction between the metal parts.

A Major Style Point

It measures how cold it has to go before the lubricant evaporates. In all cases, it needs to be over 220 degrees Celsius. Thus, the potential for a fire is diminished as the oil temperature rises. - Detergency

Metal-based detergency additives have superior cleaning qualities and are added to the mix. As a result, they keep metal surfaces free of dust and dirt. They clean up the combustion chamber in two-stroke engines by removing debris from the ring pack. - Thermodynamic Stability

The engine’s working elements generate heat continuously. The oil must absorb the heat’s thermal energy to keep the marine engine from overheating. It should be thermally stable and have strong conductivity because it cools down the engine’s interior components.